May 20, 2025

In this blog post: Industrial Food Waste Statistics | Prevention vs Diversion | Sustainable Food Waste Solutions for Industrials | What to Look For in a Diversion Solution | The Trusted Diversion Solution for Industrial Food Waste

Summary: This post offers insights for manufacturers, distributors, wholesalers, and storage companies on what to look for in food waste diversion solutions.

Nearly 18 percent of surplus food is created in the post-harvest and pre-retail supply chain, during the transit, manufacturing, storage, and distribution phases. More than 85% of that surplus food isn’t consumed by people or animals, but instead goes to waste destinations, with landfills being the single biggest destination, according to a recent report from ReFED. This surplus food cost industrial food companies approximately $41.9B in losses in 2023, a number which is sure to continue climbing in 2025 as food and commodity prices continue to fluctuate.

Food waste isn’t just a drain on business revenue; the climate impacts from wasted food such as methane emissions are introducing more risk into the market, with extreme weather conditions making it harder to grow, store, and ship food.

As new regulations emerge to prevent food from going to waste across the supply chain, it’s imperative that industrial food companies find efficient, cost-effective solutions to prevent and reduce waste. This post offers a detailed strategy for industrial food companies such as manufacturers, distributors, wholesalers, and storage businesses, on how to effectively reduce waste and what to look for in a diversion solution.

Should Industrial Food Companies Prioritize Food Waste Prevention or Diversion?

While solutions such as predictive software that can identify operational inefficiencies will be crucial to long-term prevention, industrial operators need more immediate solutions to address the inevitable surplus and waste that result from machinery breakdowns, human error, and consumer demand fluctuation, as well as food manufacturing byproducts that aren’t edible or donatable. This excess food material is complex –– it includes many different types of materials (liquid and solid, packaged and unpackaged) in large volumes that need to be managed securely, in compliance with local regulations, with certified, verified destruction.

Wasted food is also an urgent climate issue: nearly 58% of methane emissions from municipal solid waste (MSW) landfills comes from wasted food, and methane has 80 times the warming power of carbon dioxide over the first 20 years. Unconsumed food that is diverted from a landfill today will prevent greenhouse gas emissions (GHGs) immediately and reduce the intensity of GHGs in the next 100 years. Because of this urgency, states across the country are implementing new legislation with a combination of incentives and requirements to encourage industrial food companies to divert their waste now or in the very near future. For some states, these organic waste bans have already gone into effect, while other states are in the process of shaping their own organic waste legislation for the first time.

So, while prevention is important, it is only one piece of the puzzle that will solve the wasted food crisis. Diversion solutions are a necessity for regulatory compliance both now and in the future, and to reach our climate goals in time. Industrial food businesses need a diversion solution that is designed to comply with regulations and provide immediate, certifiable impact.

Sustainable, Compliant Waste Diversion Solutions for Industrial Food Waste

So, what are the diversion solutions that can sustainably manage industrial scale wasted food and food byproducts, in compliance with emerging legislation? There are two key questions that industrial food companies should ask when looking for a diversion solution:

- Can this solution accept all – or most – of our food waste and food byproducts?

- What does this solution do with that waste, and is it the most sustainable approach?

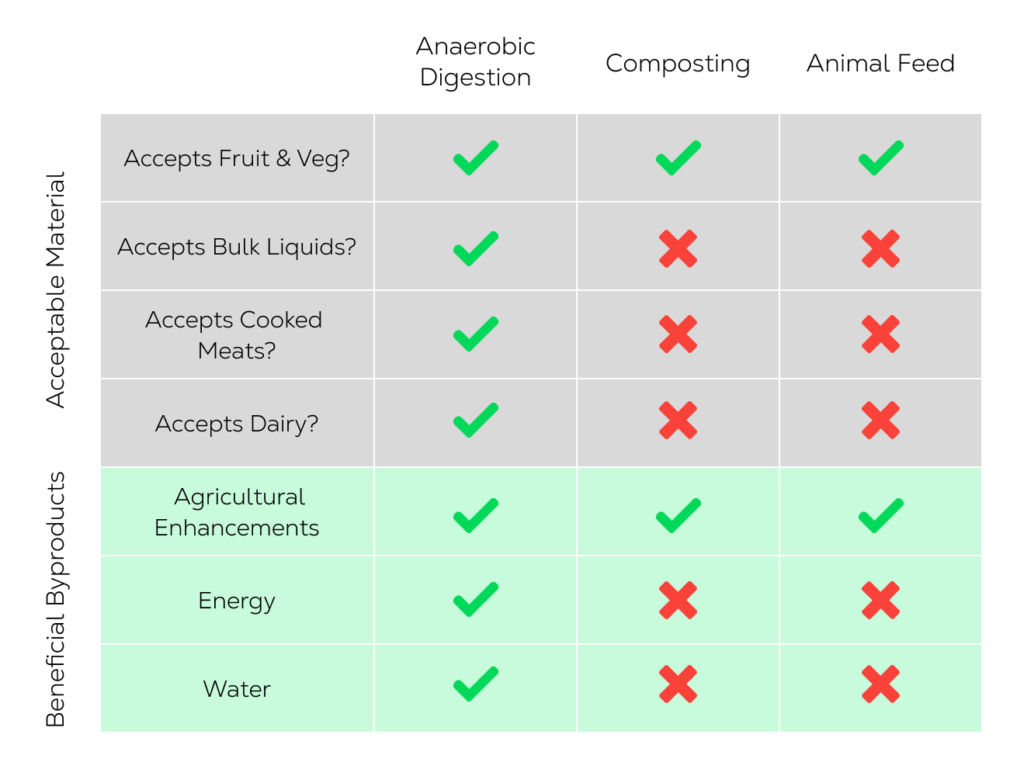

Composting typically avoids large volumes of liquids, dairy, and meats due to odor, pest, and pathogen concerns, and for this reason, it alone cannot handle the volume of industrial food material that most manufacturers and distributors need to dispose of.

Animal feed is another potential method, but like with compost, not all foods are acceptable, and regulations (both federal and state) limit use of certain materials, especially post-consumer and animal-based waste, or require intensive treatment.

Anaerobic digestion, by contrast, is a highly versatile method that can accept many materials that other methods cannot, and in large quantities, making it key to industrial-scale diversion. Additionally, an analysis by the EPA found that anaerobic digestion has a greater potential for reducing GHG emissions compared to composting and other alternatives because it produces renewable natural gas, which will ultimately help reduce our dependence on fossil fuels.

What to Look for in an Industrial Food Waste Diversion Vendor

For food manufacturers, distributors, wholesalers, and storage companies looking to avoid compliance challenges and make an immediate impact on their waste reduction goals, here are some things to consider when evaluating diversion solutions:

- Look for a partner that has nationwide infrastructure to support your business, and that can integrate seamlessly with your existing operations.

- Choose a diversion program that can offer insights and strategies to help you optimize your waste diversion efforts over time and that integrates seamlessly with your operations.

- Look for a solution that accepts a variety of material in large volumes (including product recalls, expired or contaminated loads, beverage waste, and bulk liquids) and ensures secure, certified destruction as well as regulatory compliance.

- Measurement and data are key to effective waste reduction. The right solution will help you identify trends to prevent waste in the long term, while effectively diverting unconsumed food material from the landfill in the short term.

- Look for a circular solution that puts all of your non-donatable, unconsumed food material and organic byproducts to beneficial use.

- Choose a transparent solution with a partner that readily shares how their process works and can substantiate sustainability claims with impact reporting. These sustainability reports should outline in detail what environmental benefits are achieved when they process your material.

- Make sure your partner will responsibly depackage your unsold food products to prevent microplastics from contaminating byproducts for agriculture such as animal feed, digestate, or compost. (A reliable depackaging solution will also reduce your operational costs because you won’t have to invest in the time, labor, or technology to depackage it yourself.)

With so much heightened uncertainty and volatility in the food market in 2025, you need a diversion solution you can trust, that is transparent and integrates with your existing operations and reduces risk.

Divert: The Trusted Solution in Food Waste Diversion

With 17 years of experience, Divert is the leader in managing unconsumed, non-donatable food and food byproducts. Trusted by the nation’s leading food companies, we’re driving sustainable industry change on a national scale:

- Our solutions are simple and integrate seamlessly with your existing operations to keep your team focused on your core business and reduce your overall waste management costs. These capabilities include depackaging, transportation support where available, scheduling, and more.

- We handle complexity with care. We accept a wide variety of materials (from commingled slurries to line casualties to large recalls of fully packaged products and more), and we offer secure, certified destruction with support for even the most demanding confidentiality requirements. We do all of this to enable your regulatory compliance.

- We help you make an immediate and lasting impact. Our anaerobic digestion process transforms unconsumed, non-donatable food products and organic byproducts into renewable natural gas to power local communities, reducing dependence on petroleum-derived energy.

- We provide insights to drive better decision-making, right-size your waste over time, and understand how regulations are impacting the business.

- We’re scaling nationwide infrastructure to be within 100 miles of 80% of the U.S. population.

To date, we’ve helped our customers prevent more than 3.2 billion pounds of unconsumed, non-donatable food and organic byproducts from going to waste, and we’re scaling rapidly to serve your business across the United States. Whether you’re a manufacturer, distributor, wholesaler, or storage company, we have the diversion solutions to help you achieve immediate and lasting impact. Contact us to learn more about our solutions.