June 3, 2025

In this post: Carbon footprint | Odor from food material | Contamination from packaging | Water reuse | The Trusted Diversion Solution

Summary: Preventing unconsumed food from going to landfills and transforming it into beneficial products like biogas or fertilizer comes with many environmental considerations. This post covers the environmental challenges of processing unconsumed and inedible food and how Divert does so responsibly.

Divert’s facilities receive thousands of pounds of unconsumed and inedible food per day from commercial and retail food businesses to transform it into renewable energy and soil enhancements for agriculture through a process known as anaerobic digestion. We currently support more than 7,500 customer locations nationwide, operate 14 facilities, and intend to expand to 30 facilities across the U.S. to be within 100 miles of 80% of the population. To date, we’ve processed more than three billion pounds of unconsumed food.

With all of that food material coming to our facilities, there are important environmental considerations to address, such as how to prevent additional emissions, maintain clean and safe facility conditions, use water responsibly, and separate unconsumed food from its packaging. On our mission to prevent food from going to waste, we are committed to doing so in an environmentally responsible way that our customers and communities can trust.

Here’s an overview of how Divert addresses the environmental factors of transforming unconsumed food into renewable energy.

Factor #1: How to transport and process unsold food products while controlling our carbon footprint.

Sending tons of unconsumed food products from hundreds of locations to an organics processing facility could result in excessive greenhouse gas emissions and a large carbon footprint. But at Divert, we’ve developed a way to mitigate this through our reverse logistics process, which utilizes customers’ existing logistics network. Unsold food from grocery stores returns to distribution centers in closed bins on the return trip from food retailers’ regular truck delivery routes.

The reverse logistics process has several benefits:

- There are fewer trucks on the road, because the reverse logistics process removes the need for trucks to make a separate trip to pick up the food, or to send the food to landfills from the stores. This leads to less fuel consumed and fewer emissions.

- This also leads to less traffic for customers and their neighbors.

- The process fits seamlessly within customers’ existing operations and logistics routes so that it is easy to implement, sustain, and scale across every location.

- The process reduces total carbon emissions, boosting the environmental impact customers are already making by reducing their wasted food volumes.

Factor #2: How Divert maintains clean, safe conditions and minimizes harmful odors from food material when transporting and processing it into renewable energy.

Handling unconsumed food products doesn’t have to be messy. Our operational procedures account for worker safety and environmental regulatory requirements in a few important ways:

- Divert bins keep food material sealed during transport, and all packaged food material stays in its original container until it is ready to be processed.

- Our facilities are closed environments, which means no food products sit out in the open air.

- Our operation runs continuously so that organic material is fed into our system promptly after it is received.

This approach prevents naturally occurring odors that might have otherwise emerged from a landfill or open compost pile, while also providing other co-benefits:

- It frees up transportation trailers to make way for new inbound loads, keeping the process efficient and timely for our customers.

- We’re able to collect and deliver timely data on bin contents to our customers to help them optimize their decision-making on purchasing orders, mark-downs, and donations.

Factor #3: How to prevent contamination from food packaging when processing food material through anaerobic digestion.

If we want to keep food out of landfills and effectively capture the energy and nutrient value for beneficial use, then it is crucial that we responsibly separate food from its packaging to prevent plastic, glass, and metal remnants from contaminating the resulting products, such as renewable natural gas or agricultural soil.

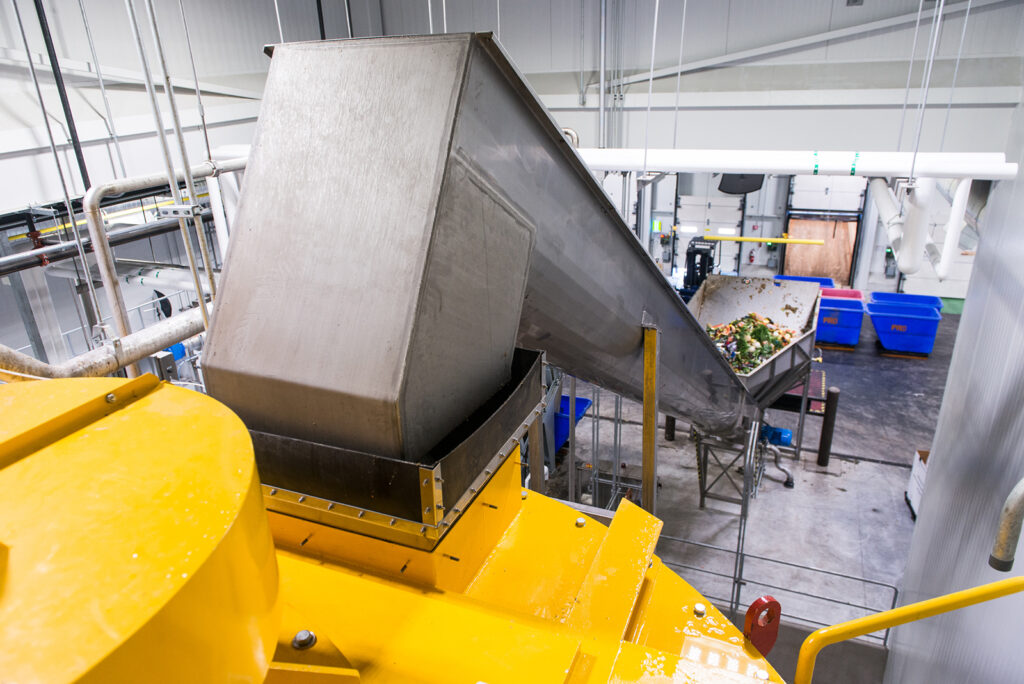

At Divert, we manage this through a multi-step depackaging process:

- First, we leverage our data and technology as well as the expertise of our field teams to provide customer training and education. In doing so, we help our customers refine and reduce the material they send to our facilities to prevent recyclable packaging or waste materials from being processed.

- Second, we use our proprietary depackaging technology to gently separate non-biodegradable packaging from organic material without shredding it. The organic material is liquified into a slurry and screened multiple times with filters and membranes to remove contaminants and purify the slurry for anaerobic digestion, as well as soil enhancements for agriculture.

Learn more about our approach to responsible depackaging.

Factor #4: How to recover and reuse water from unconsumed food material during anaerobic digestion.

In aggregate, food material is mainly water. When food goes to waste, so does the water embedded within it. In a landfill, that water becomes toxic leachate by picking up contaminants as it percolates through the trash. When we put unconsumed food to productive use rather than throwing it away, we can recover the water content, treat it, and reuse it.

Divert’s anaerobic digestion process rescues and reuses water from the unconsumed food material it processes. This approach minimizes fresh water intake compared to some traditional industrial operators, which typically consume large volumes of fresh water without any water reclamation for their processes. While Divert still uses fresh water, our Integrated Diversion & Energy facilities are net exporters of water. This means our Integrated Facilities send more water to treatment plants than the fresh water we consume. This nuanced approach highlights the balance between resource recovery and local water management.

The Trusted Solution for Managing Unconsumed Food

When Divert opens a facility in a new location, we design them intentionally to create environmental benefits, mindful of our customers’ and the region’s waste reduction goals. The infrastructure, technology, and processes we’ve built have set new industry standards, helping our customers to prepare for tomorrow’s regulations, meet current requirements with confidence, and achieve their waste reduction, resource management, and sustainability targets.

We also strive to be a good neighbor in every community we join by building solutions and processes that facilitate food recovery, protect local resources, and provide jobs.

Since 2007, Divert has played a leading role in addressing the human and environmental crises created by wasted food through our holistic Prevent, Provide, Power™ approach. Divert is trusted by the nation’s leading food companies and retailers to manage their unsold food, including Blue Diamond, Ahold Delhaize, Albertsons, Kroger, and more. The carbon-negative renewable energy created from our anaerobic digestion facilities is powering communities, and bringing states closer to achieving their climate and clean energy goals. Together with our customers and partners, we’re scaling nationwide infrastructure to prevent food from going to waste.